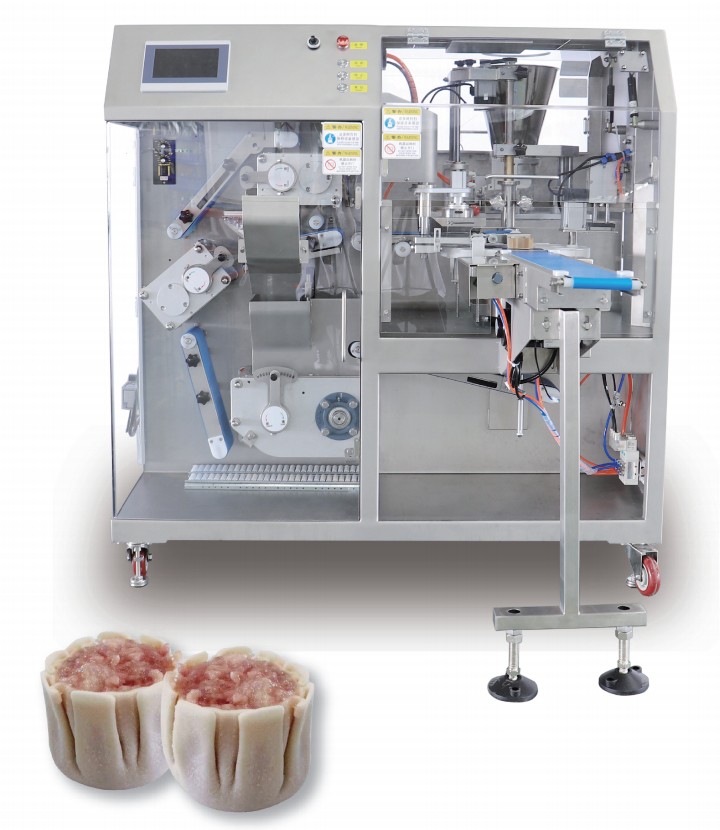

XSJ10B Dumpling Machine - Handmade Dumpling

Designed to automatically produce ruffle-edged dumplings in collaboration with corresponding mechanisms and molds. This dumpling type is suitable for boiling, steaming, pan-frying, and deep-frying, meeting diverse customer needs across different occasions.

Easy Operation

The machine features only four operation buttons with an ergonomic design. It requires minimal training for production personnel, who can quickly learn to operate it and start working.

Convenient Cleaning

The dough sheet system adopts a cantilevered design, leaving no hard-to-clean corners. The filling system is equipped with a tool-free quick-disassembly design, allowing the entire machine to be disassembled, cleaned, and reassembled in less than 30 minutes.

Cost-Effective and High Efficiency

The equipment incorporates a patented new design for dough sheet formation and shaping, along with a central automatic dough-recycling mechanism. Compared to traditional dumpling machines, it has lower requirements for dough and filling, while achieving higher dough utilization and product yield.

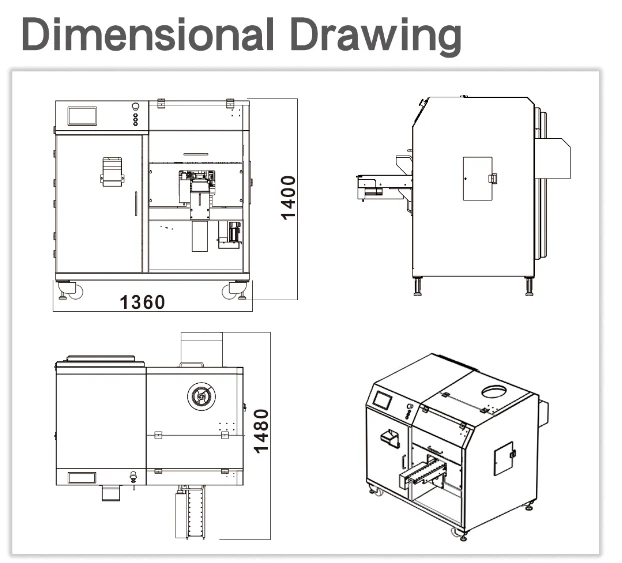

| Model | Dumpling weight | Skin weight | Stuffing weight | Production speed | Machine size | Machine weight |

| XSJ10B | 23 | 10-11 | 12-13 | 40-50 | 1360*1550*1440mm | 550kg |

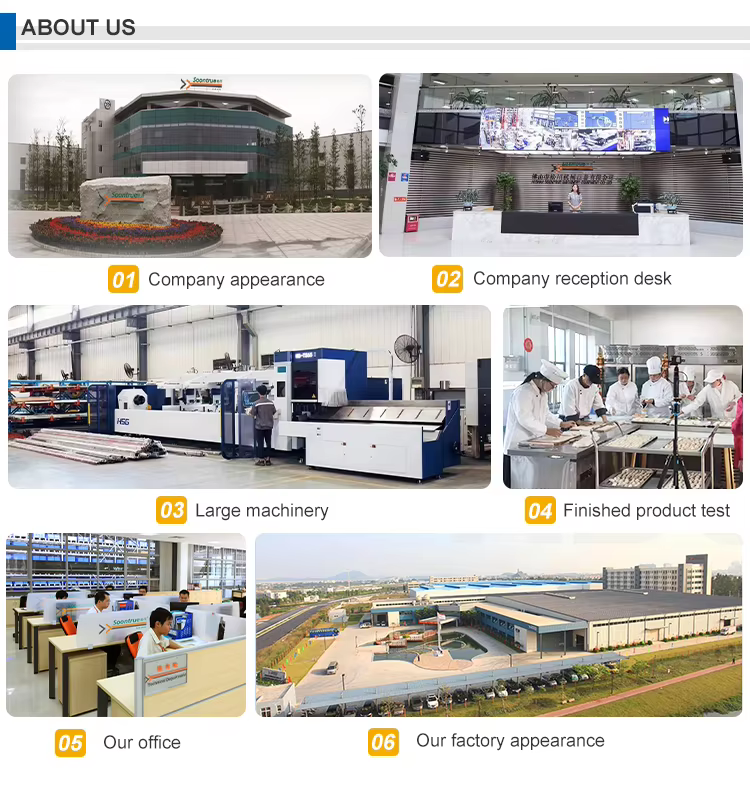

XSJ-Elite Modular Dumpling System

Model: XSJ10A | Year: 2025

Overview

The XSJ-Elite Modular Dumpling System is engineered for diversified culinary operations, including:

Catering chains

Institutional meal programs

Industrial food production facilities

Its innovative modular architecture enables customized configurations to meet evolving market demands across the Asia-Pacific and North American regions.

Key Features

High-Efficiency Design

Compact footprint with industrial-grade production capacity.

Proprietary triple-layer dough processing mechanism ensures uniform thickness and preserves natural dough elasticity.

Delivers consistent texture for both traditional and innovative dumpling varieties.

Smart Manufacturing Integration

Ideal for smart food factories and cloud kitchen ecosystems.

Scalable solutions to optimize workforce efficiency and accelerate recipe development cycles.

Operational Flexibility

Component-based design allows rapid maintenance and functional upgrades.

Supports adaptation to dynamic market trends while maintaining cost-effective operations.

Target Applications

Large-scale food production

Automated kitchens requiring high output and consistency

Markets prioritizing modularity and future-proof equipment